Our Rocking Chair Splats

The splats in our chairs are curved to fit your back.

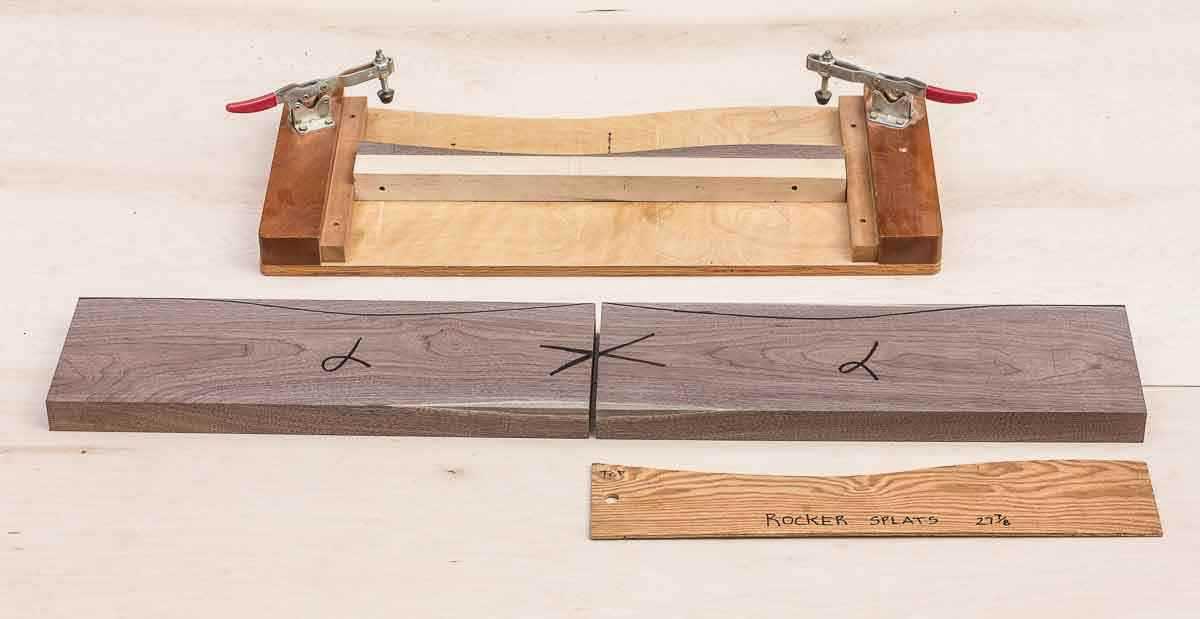

- The curve of the backsplats was found by testing and is proven by review.

- We select so the growth rings are perpendicular to the edge that will become the face of a splat: the strongest orientation.

- We choose two blocks of wood, end to end in the board, that will make at least four splats each.

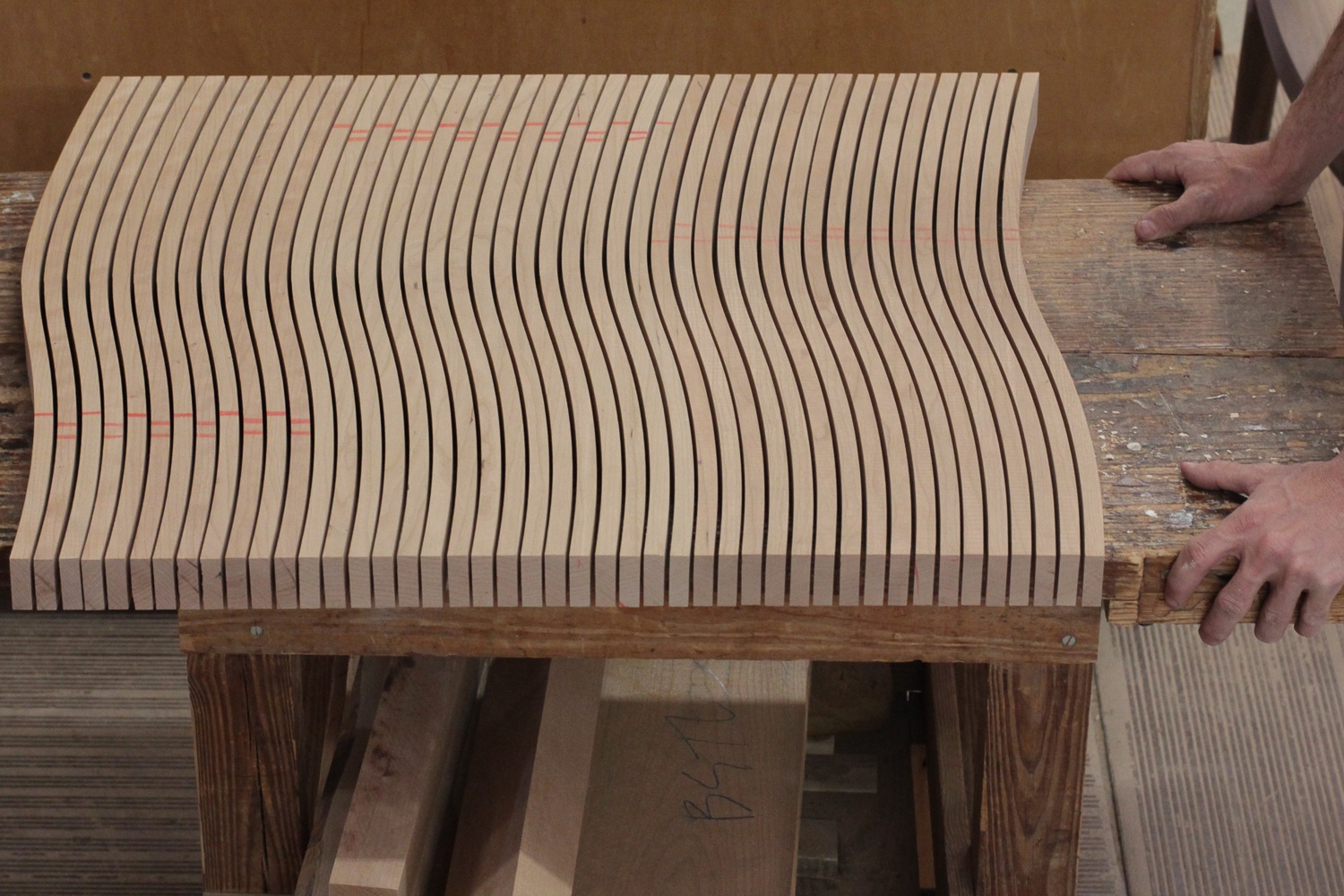

- We produce them with precision. Note the "run" of splats on the dolly in the photo above.

We use a fixture to guide the splat blank over the pattern shaper and true its face to line and curve.

With the help of a marking gauge and a point guide clamped to the bandsaw table, we cut a splat from the block, at the same time making a rough cut for the face of the next splat.

And so on we go:

One of us truing the face of a splat at the shaper,

and one of us sawing the splat from the block at the bandsaw.

We sand out the milling marks and fit the thickness of the splat at our shop-built chairback sander.

We round over the edges on the router table.

We sand to fit.

They fit.

chair seat and splats

Navigation

Home

Footstools

Side Tables

Floor Protection

Videos

Shop Log

Contact Us

Cherry Rocking Chairs

Walnut Rocking Chairs

Maple Rocking Chairs

Porch Rockers

Mesquite Rocking Chairs

Special Edition Rockers

Dimensions

360° Views of our Rocking Chair

Custom Rocking Chairs

Wooden Rocking Chairs

Comfortable Rocking Chairs

Chairs for Rocking Babies

Rocking Chair for Retirement

The Gift of a Rocking Chair

Is the Weeks Rocker a copy of the Maloof Rocker?

Directory of Handmade Rocking Chair Makers

Press Kit

Woodworker West, 2023

Saturday Evening Post, 2021

Houston Family Magazine, November 2018

Hill Country View, May 2018

PEC: Heart of the Hill Country, March 2018

Wimberley Visitor's Guide, Spring and Summer 2018

Esquire, April 2016

Dallas Modern Luxury, Fall 2010

Edible Austin, Fall 2010

Edible Austin, Summer 2010

Practical Ecommerce, March/April 2008

Ranch & Rural Living, January 2007

Denver Post, June 2006

Southern Living, June 2006

Northwest Certified Forestry, Spring 2006

Dallas Morning News, December, 2005

Furniture & Cabinet Maker, April 2004

Woodshop News, March 2004

The Australian Woodworker, June 2003

New Texas, November 2001

Texas Co-op Power, December 1999

The Art of Living, May 1999

Texas Monthly, May 1999

Cabinet Maker, April 1999

Lake & Country Living, March 25, 1999

The Woodworker, March 1999

Woodshop News, February 1999

Interiors & Sources, January/February 1999

Custom Woodworking Business, January 1999

Austin American-Statesman Life & Arts, December 1998

Modern Woodworking, December 1998

Wimberley View

Wimberley View, March 1993